Like the weather in Texas, the moon’s temperature varies drastically over the course of its day and night cycle. The moon’s surface can reach scorching temperatures as high as 250 degrees F during the day and a frigid 208 degrees below zero at night.

These dramatic fluctuations in temperature create a challenge during lunar missions – keeping payload, whether that’s astronauts aboard a spacecraft or an experimental device on a rover, from becoming too hot or too cold.

With lunar explorations on the horizon, including putting astronauts back on the moon by 2024, NASA is investing $2 million in cutting-edge thermal technology to make regulating temperatures during missions possible.

This technology will be developed by a team of researchers from Texas A&M University, the Boeing Company and Paragon Space Development Corporation. The team is focused on creating shape-shifting technology to adjust thermal control systems automatically.

“Our proposed solutions incorporate shape-shifting metals that adjust their own heat rejection based on how hot or cold they are, so it solves the problem for us,” said Dr. Darren Hartl, assistant professor in aerospace engineering and head of the Multifunctional Material and Aerospace Structures Optimization (M2AESTRO) Lab at Texas A&M.

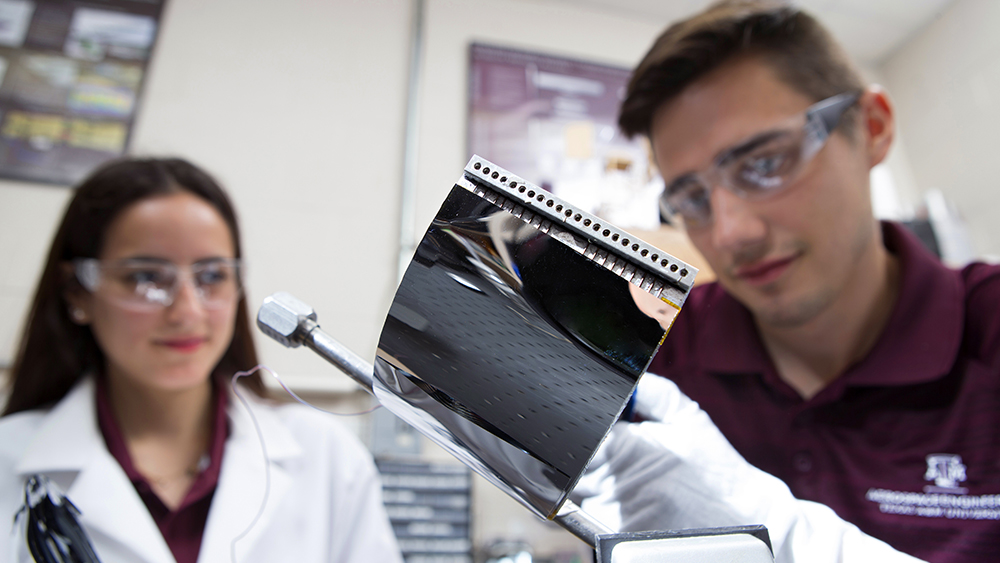

Hartl and his team have a successful history partnering with both Boeing and Paragon on shape memory alloy (SMA) technology. Most recently, Hartl and Dr. John Whitcomb, professor in aerospace engineering, have worked on an idea with Paragon to create a morphing radiator composed of SMAs.

Prototypes of the morphing radiator were developed by former graduate students Christopher Bertagne, now at NASA’s Jet Propulsion Laboratory, and Patrick Walgren, current Ph.D. student. They successfully tested the prototypes in a small thermal vacuum chamber at NASA’s Johnson Space Center.

The recent funding from NASA, awarded through the Tipping Point initiative, will launch the SMA-based thermal control technology into its next phase.

“It’s incredibly rewarding to be a part of the team that advanced this technology to its current state and to learn that NASA is committed to further maturing the concept,” said Walgren.

Texas A&M researchers will begin their part of the project in the spring, which includes further development of the morphing radiator as well as the modeling and optimization of an accompanying thermal switch, also composed of SMAs. These thermally sensitive technologies represent uncharted territory, yet are critical to the operations of future space expeditions.

“It will be another successful example of morphing structures enabling something that couldn’t have been done before,” said Hartl. “It will be another example to the aerospace industry that you can have a structure adapt itself to its environment.”