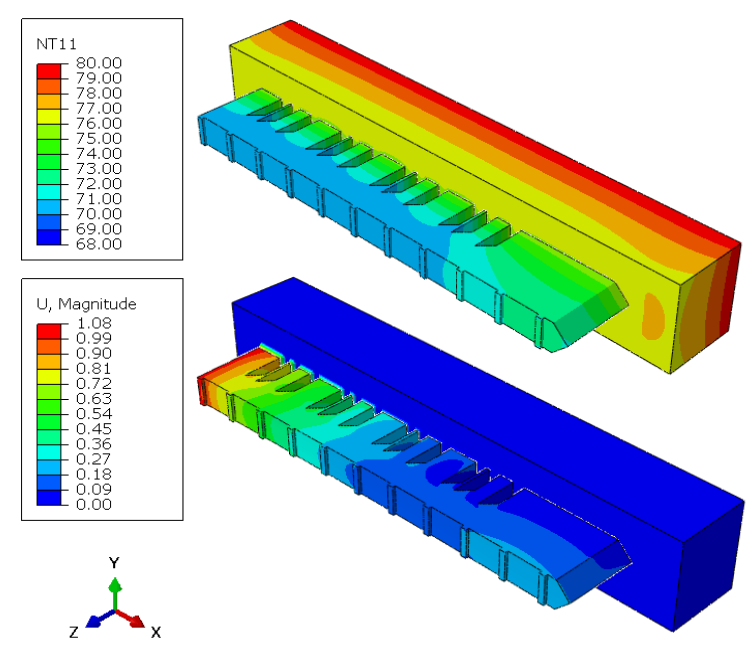

Additive Manufacturing Analysis in Abaqus

Additive manufacturing (AM) offers a broad design space capable of creating complex geometries. The ability to spatially control properties in a component via the control of processing conditions will extend AM capabilities. The tools developed in this project primarily focus on systematic AM processing plans to simulate AM components with complex geometry and manipulated heterogeneity. Additive simulation is a complex analysis considering process parameters, print geometry, and material properties. Each of these areas is focused on to complete the project objectives. Once heterogeneous additive tools are developed, a global optimization algorithm can demonstrate a complete design space. This framework will take an existing structure and run topology optimization, assess constraints, apply heterogeneous properties, and evaluate part performance.